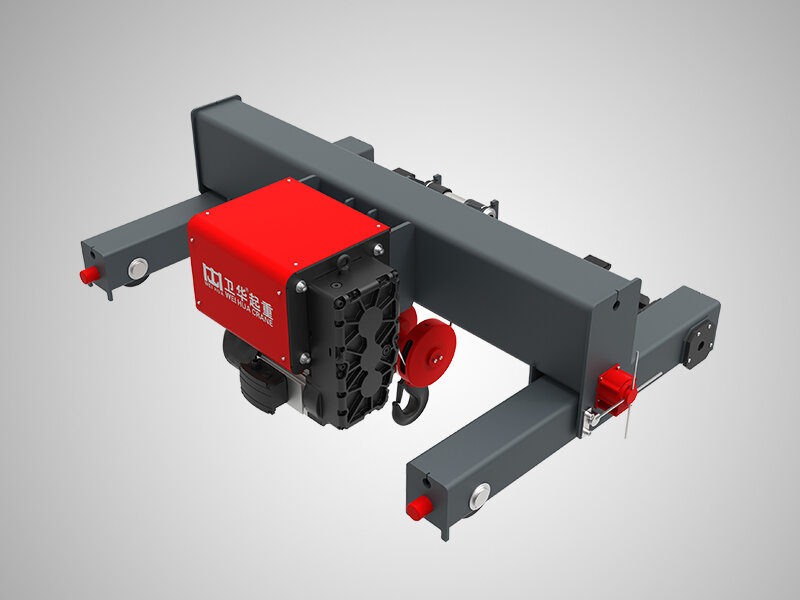

Electric Rope Hoist

Capacity: 1t~20t

Lift Height: 6m~36m

Fitted on I-beam monorail girder

Features:

1. Modular design.

2. Less headroom, hight lift height.

3. World famous motor, reducer, electricals and other components, long service life.

4. FEM standard.

5. Safe and simple operation.

6. cost-effective.

Features:

Hoist Motor:

Rugged 12/2-pole cylindrical-rotor motor (selection of frequency conversion)

Less vibration, quiet running.

Thermal contacts to protect against overheating.

Designed for extended operating periods, classified in accordance with FEM.

IP 54 enclosure.

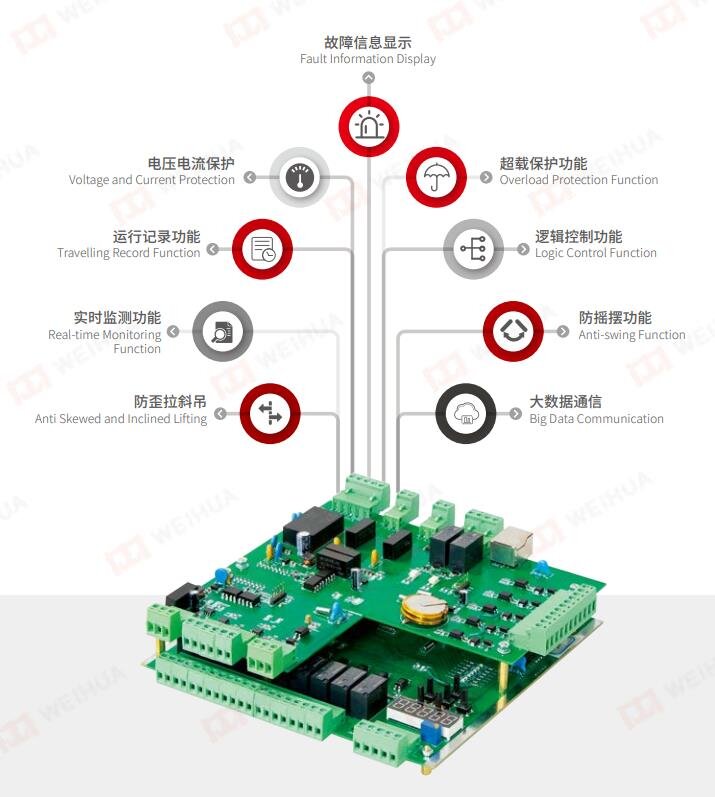

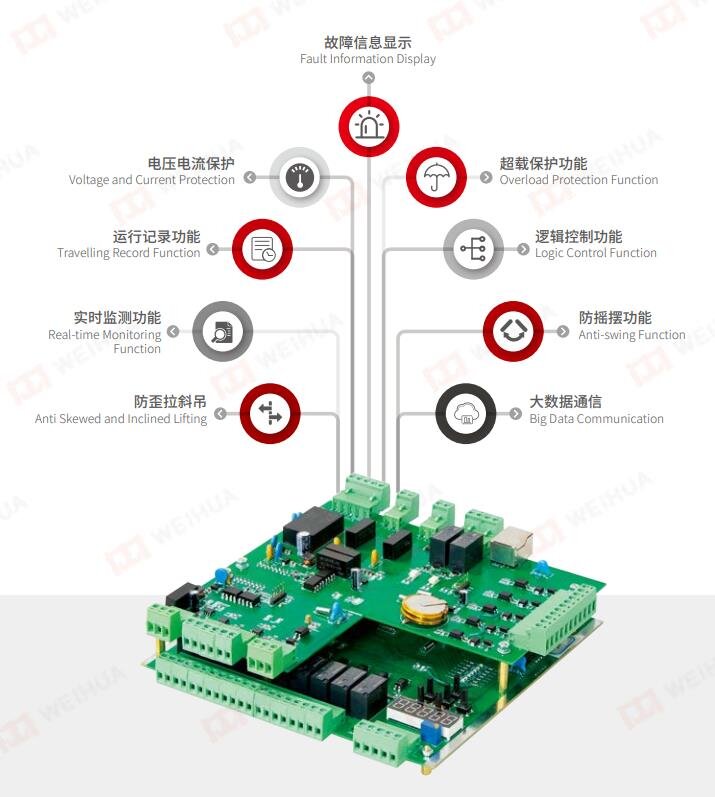

Control System:

Conventional contactor control.

Frequency conversion operation.

Electronic module for control of time functions.

Overload protection fitted as standard for increased safety.

Control by means of DST control pendant (optional).

Ergonomic and rugged design with 7 or 9 buttons.

Emergency off switch fitted as standard.

Accurate 2-pole rotating limit switch.

Brake:

DC disc brake with brake release monitoring (optional)

Min. safety factor of 1.8.

Rapid response through integrated brake module.

Rope Drum Guide:

Generously dimensioned drum for long rope service life.

Precisely machined rope grooves.

Rope guide made of heavy duty composite material.

Reliable fleet angle up to ±4 degree without physical contact between rope and rope guide.

Gear Box:

3-stage, helical gear reducer.

Low running noise;

Lifetime lubrication.

Hook Block:

Ergonomically designed and operator friendly.

Pulley made of special materials with low noise

Smooth running.

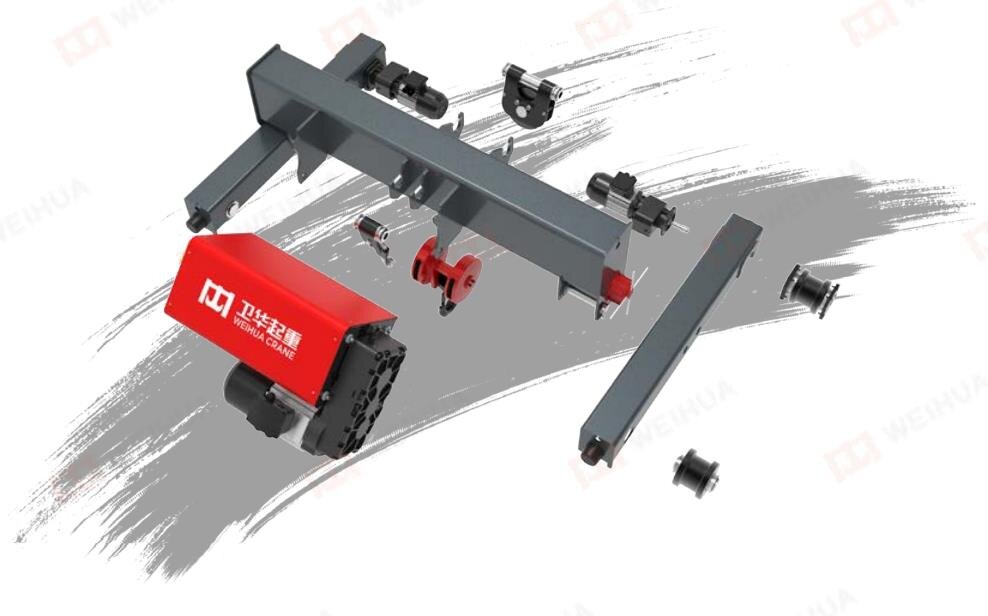

Capacity: 1t~80t

Lift Height: 6m~36m

Fitted on double girder cranes

Features: Good diversity and adaptability: 4 models (chain type, monorail type, double girder type and fixed type), 3 sizes, 5 hook paths, 6 speeds.

Features:

Hoist Motor:

Rugged 12/2-pole cylindrical-rotor motor (selection of frequency conversion)

Less vibration, quiet running.

Thermal contacts to protect against overheating.

Designed for extended operating periods, classified in accordance with FEM.

IP 54 enclosure.

Control System:

Conventional contactor control.

Frequency conversion operation.

Electronic module for control of time functions.

Overload protection fitted as standard for increased safety.

Control by means of DST control pendant (optional).

Ergonomic and rugged design with 7 or 9 buttons.

Emergency off switch fitted as standard.

Accurate 2-pole rotating limit switch.

Brake:

DC disc brake with brake release monitoring (optional)

Min. safety factor of 1.8.

Rapid response through integrated brake module.

Rope Drum Guide:

Generously dimensioned drum for long rope service life.

Precisely machined rope grooves.

Rope guide made of heavy duty composite material.

Reliable fleet angle up to ±4 degree without physical contact between rope and rope guide.

Gear Box:

3-stage, helical gear reducer.

Low running noise;

Lifetime lubrication.

Hook Block:

Ergonomically designed and operator friendly.

Pulley made of special materials with low noise

Smooth running.

Copyright© 2024 TEKNINDO Crane Supply And Service | Design by: Webseonesia